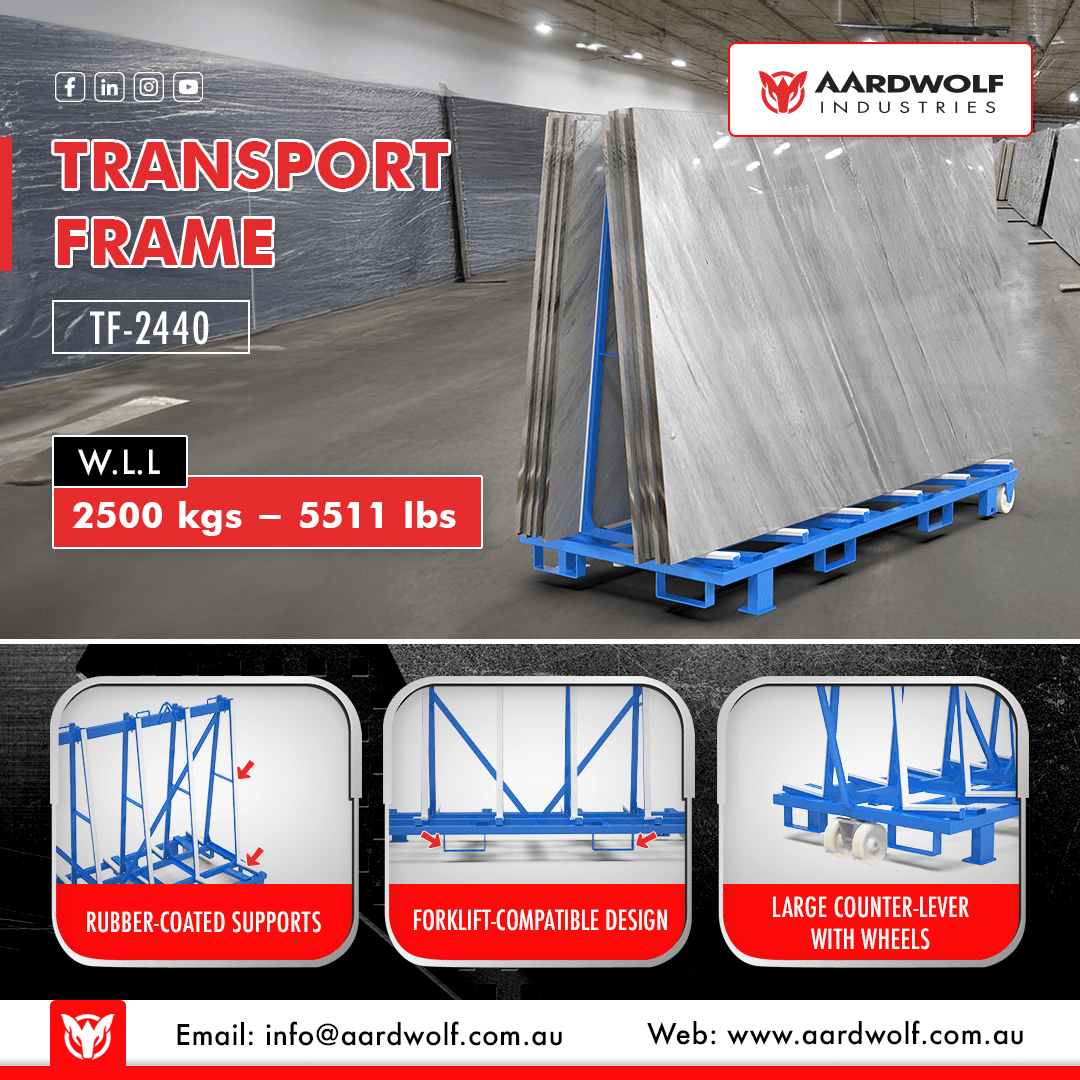

A transport frame is a robust, engineered structure designed to support, secure, and safely move heavy materials across various industries.

A transport frame is a robust, engineered structure designed to support, secure, and safely move heavy materials across various industries. From construction sites to stone fabrication workshops, a well-designed transport frame plays an essential role in ensuring the safe handling of materials such as stone slabs, concrete panels, and other heavy components. In this comprehensive guide, we delve into the world of transport frames, exploring their design, applications, and benefits. We will also discuss how transport frames contribute to effective stone storage, slab storage, and overall stone transport and stone transportation processes. Moreover, we’ll highlight how modern innovations are revolutionizing stones transportation with enhanced safety and efficiency.

Introduction to Transport Frames

Transport frames are the backbone of material handling in industries where heavy items need to be moved without damage. Essentially, these frames provide a stable base for loads during transit, ensuring that every move is secure. The concept of a transport frame isn’t limited to just moving items—it also encompasses safe storage solutions. For instance, effective stone storage and slab storage depend on frames that minimize the risk of damage, ensuring that valuable materials remain in pristine condition from the moment they are extracted to the time they are installed.

A transport frame also functions as a transportation frame when integrated with other machinery, such as cranes and forklifts, to facilitate the entire process of stone transport. This integration is vital, especially when dealing with delicate materials like stone, which can be easily damaged if mishandled. High-quality transport frames, such as the transport frame, are designed to work in tandem with devices like the lifting clamp to ensure that every load is lifted, moved, and stored with precision.

Key Components of a Transport Frame

Structural Integrity and Design

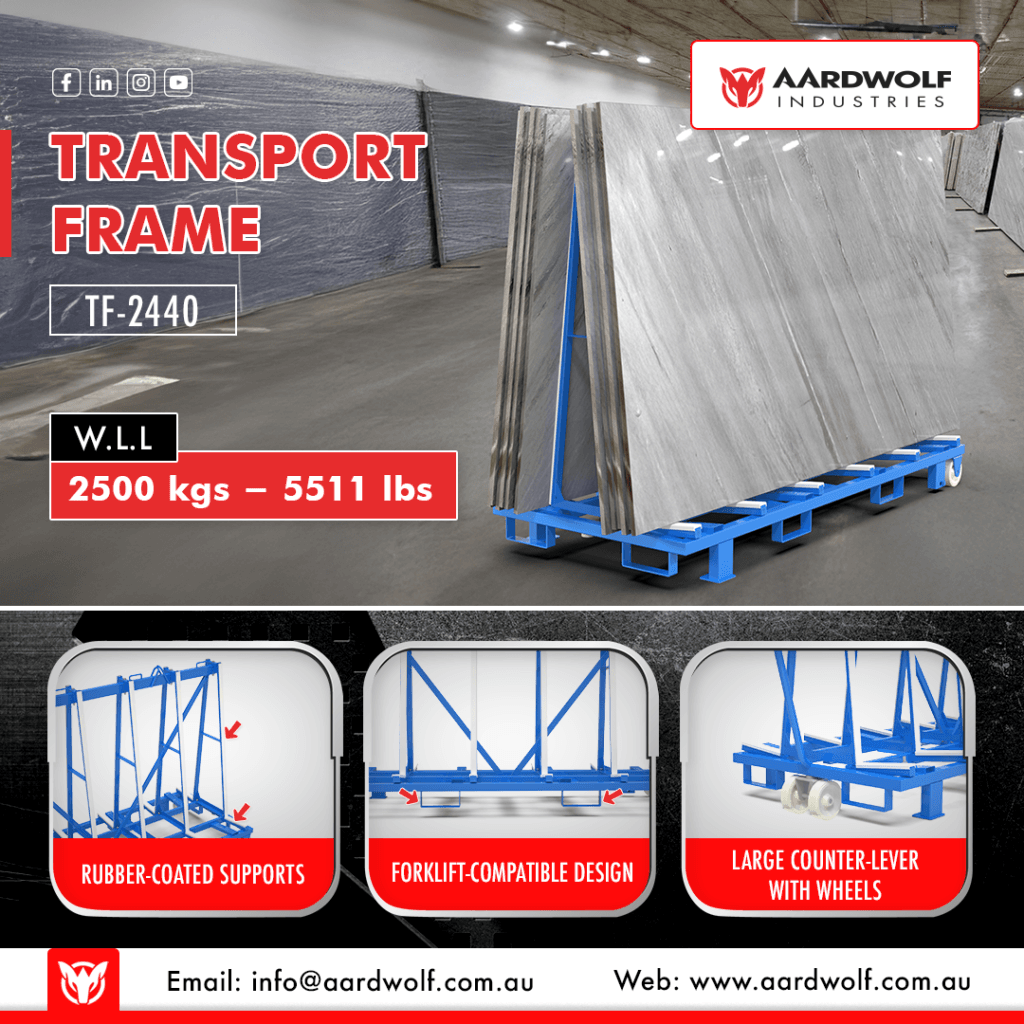

The primary function of a transport frame is to provide a stable structure that can handle heavy loads. The structural design involves:

- High-Strength Materials: Transport frames are usually constructed from hardened steel or composite materials that offer high durability and resistance to environmental wear.

- Cross-Bracing: This feature reinforces the frame, providing extra support during the movement of heavy items. Cross-bracing ensures that the frame does not deform under heavy loads.

- Adjustable Mounting Points: These allow operators to customize the frame to suit different load sizes and shapes, which is crucial when dealing with various materials in stone transport.

Integration with Lifting Systems

Modern transport frames are often designed to integrate seamlessly with advanced lifting equipment. For example, many transport frames are paired with a lifting clamp, which securely holds the material in place during lifting and transportation. This integration ensures that the weight is distributed evenly, reducing the risk of damage. The synergy between the transport frame and lifting equipment makes it possible to manage everything from stone transportation to stones transportation with ease.

Applications of Transport Frames

Transport frames have a wide array of applications across different sectors. Below are some of the key industries where transport frames are indispensable.

Construction and Building Projects

In the construction industry, the safe movement of heavy building materials is crucial. Transport frames are used to move large concrete slabs, stone panels, and metal components from one point to another. This not only streamlines the construction process but also minimizes the risk of material damage and workplace accidents. By integrating transport frames with transportation frames, construction companies can achieve a higher degree of safety and efficiency on job sites.

Stone Fabrication and Installation

For stone fabricators, the precision handling of natural stone is paramount. Stone storage and slab storage systems rely on transport frames to keep stone slabs secure and undamaged during both transit and storage. Whether the stone is being moved from a quarry or is being transported to a job site for installation, a reliable transport frame ensures that the material is handled with the utmost care. This is particularly important in projects such as high-end residential and commercial installations, where any damage to stone surfaces can result in significant cost overruns and delays.

Industrial Manufacturing and Material Handling

In industrial settings, transport frames are used to manage the movement of heavy metal plates and other substantial components. The versatility of transport frames makes them suitable for various manufacturing processes where the safe handling of heavy loads is a priority. Integrating transport frames with automated systems can streamline operations, allowing for quick adjustments and efficient material flow. This application is crucial in sectors where stone transport and stone transportation must be executed on a tight schedule.

Transportation of Multiple Units

When multiple units need to be transported, such as during bulk shipments of stone or concrete, transport frames are key to maintaining order and safety. The design of modern transport frames allows for the secure stacking and transport of several items simultaneously, a process often referred to as stones transportation. This capability is particularly beneficial in large-scale projects where efficiency and the safe handling of materials directly impact project timelines and budgets.

Advantages of Using a Transport Frame

Enhanced Safety

Safety is a top priority when moving heavy materials. A transport frame provides a secure base that minimizes the risk of load slippage and damage. Its sturdy construction and integration with lifting systems help protect both the operators and the materials. This level of safety is critical in preventing accidents that could lead to costly delays or injuries.

Improved Efficiency

By providing a stable and secure platform for material handling, transport frames significantly improve operational efficiency. They allow for quick loading and unloading, reducing downtime on busy job sites. The ease of integrating transport frames with automated lifting systems means that material handling processes can be optimized for speed and accuracy, which is particularly valuable in high-volume stone transportation.

Versatility in Material Handling

One of the standout benefits of transport frames is their versatility. They can be used for:

- Stone Storage: Safely storing large stone slabs in a controlled environment.

- Slab Storage: Offering a reliable platform for storing and moving flat, heavy materials.

- Stone Transport: Ensuring that delicate and valuable materials are transported without damage.

- Stones Transportation: Handling bulk movements of stone with precision and care.

This versatility makes transport frames an essential tool for any industry involved in the handling of heavy and delicate materials.

Cost-Effective Solution

Investing in a high-quality transport frame can lead to significant cost savings over time. By minimizing the risk of damage during transit and storage, companies can avoid costly repairs and replacements. Moreover, the enhanced efficiency provided by a transport frame reduces labor costs and project downtime, ultimately improving the bottom line.

Best Practices for Stone and Slab Storage

Optimal Stone Storage

Effective stone storage is crucial for preserving the quality of the material. When using a transport frame for stone storage:

- Keep Stone Elevated: A transport frame elevates the stone from the ground, reducing exposure to moisture and contaminants.

- Distribute Weight Evenly: The frame ensures that the stone’s weight is evenly distributed, preventing cracks and other forms of damage.

- Regular Inspections: Periodically check the transport frame for signs of wear or damage, ensuring that it remains in optimal condition for long-term use.

Efficient Slab Storage

For slab storage, a transport frame provides a level and secure platform that minimizes the risk of slippage and damage:

- Flat, Stable Surface: Ensure that the frame is level to provide a stable base for large, flat slabs.

- Prevent Overloading: Always adhere to the frame’s load capacity to maintain structural integrity and safety.

- Ease of Access: Use transport frames that are designed for easy loading and unloading, which is essential during high-turnover operations.

Maintenance and Longevity of Transport Frames

Regular Inspections

To ensure that a transport frame continues to operate safely and efficiently, regular inspections are essential. This includes:

- Visual Inspections: Check for any signs of rust, wear, or structural damage.

- Load Testing: Periodically verify that the frame can handle its rated load capacity without any issues.

- Component Checks: Inspect all mounting points, cross-bracing, and other critical components to ensure they are secure.

Cleaning and Lubrication

Keeping the transport frame clean and well-lubricated is crucial for its longevity. Dust, debris, and moisture can compromise the structural integrity of the frame over time. Regular cleaning and lubrication of moving parts help maintain optimal performance and extend the frame’s lifespan.

Professional Servicing

Consider scheduling professional servicing at regular intervals. Expert technicians can provide detailed inspections, address minor issues before they become major problems, and ensure that the frame complies with all relevant safety standards.

Integration with Advanced Lifting and Transportation Systems

Combining Transport Frames with Lifting Clamps

One of the most effective ways to enhance the performance of a transport frame is by integrating it with advanced lifting systems. For instance, coupling a transport frame with a high-quality lifting clamp can greatly streamline the process of loading, transporting, and unloading heavy materials. This integration ensures that materials are handled safely and efficiently from start to finish.

Leveraging Automation for Stone Transportation

The future of stone transport and stone transportation lies in automation. Modern transport frames are increasingly being designed to work with automated systems that monitor load distribution, provide real-time feedback, and adjust operations accordingly. These smart systems not only improve efficiency but also significantly enhance safety by minimizing the risk of human error.

Enhancing Industrial Efficiency

In large-scale operations, integrating transport frames with automated lifting and transportation systems can lead to substantial improvements in efficiency. Automated transport frames can be programmed to handle multiple loads simultaneously, which is particularly beneficial for industries involved in stones transportation. This level of efficiency can reduce operational costs, improve turnaround times, and enhance overall productivity.

Future Trends in Transport Frame Technology

Innovations in Materials and Design

As technology evolves, so do the materials and designs used in transport frames. Future models may incorporate lightweight yet durable composites and advanced alloys that offer superior strength without the extra weight. These innovations are expected to enhance the efficiency of stone transport while reducing energy consumption and operational costs.

Integration with the Internet of Things (IoT)

The integration of IoT technology into transport frames is set to revolutionize the industry. With real-time data collection on load weights, environmental conditions, and structural integrity, operators will be able to monitor their transport frames remotely. This smart integration will lead to more proactive maintenance, reducing downtime and ensuring that materials are transported safely and efficiently.

Eco-Friendly and Sustainable Designs

Sustainability is becoming an increasingly important factor in industrial design. Future transport frames are likely to feature eco-friendly materials and energy-efficient systems that reduce their overall environmental impact. These sustainable designs not only benefit the planet but also lower operational costs in the long run.

Conclusion

A transport frame is much more than just a structural support system; it is a vital component in the safe, efficient, and cost-effective handling of heavy materials. Whether used for stone storage, slab storage, or facilitating stone transport and stone transportation, a high-quality transport frame ensures that valuable materials are handled with care throughout the entire process. From construction sites to industrial manufacturing facilities, transport frames are indispensable in modern material handling.

By integrating advanced features, such as automated lifting systems and IoT monitoring, the next generation of transportation frames will continue to push the boundaries of efficiency and safety in stones transportation. Regular maintenance, proper usage, and adherence to safety standards will further enhance the longevity and performance of these systems, ensuring that they remain a cornerstone of modern industry.

Investing in a reliable transport frame not only protects your materials but also contributes to smoother operations and long-term cost savings. As the industry evolves, staying informed about the latest advancements in transport frame technology will help you make strategic decisions that keep your operations at the forefront of innovation and efficiency.

With the right transport frame, you can confidently manage everything from delicate stone panels to heavy construction slabs—ensuring every step of the process is executed with precision and care. Embrace the advancements in transport frame technology and enhance your material handling capabilities for a safer, more productive future.