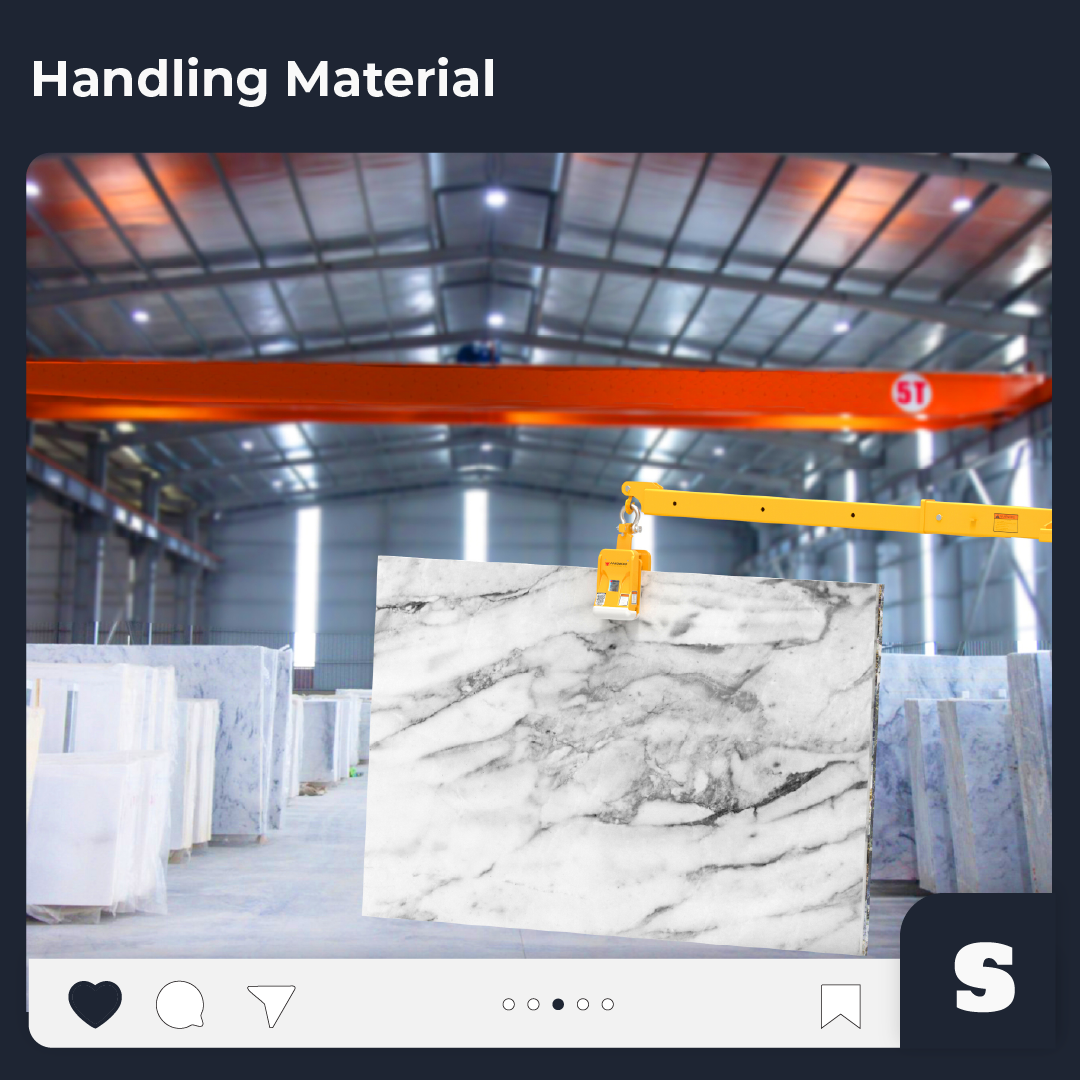

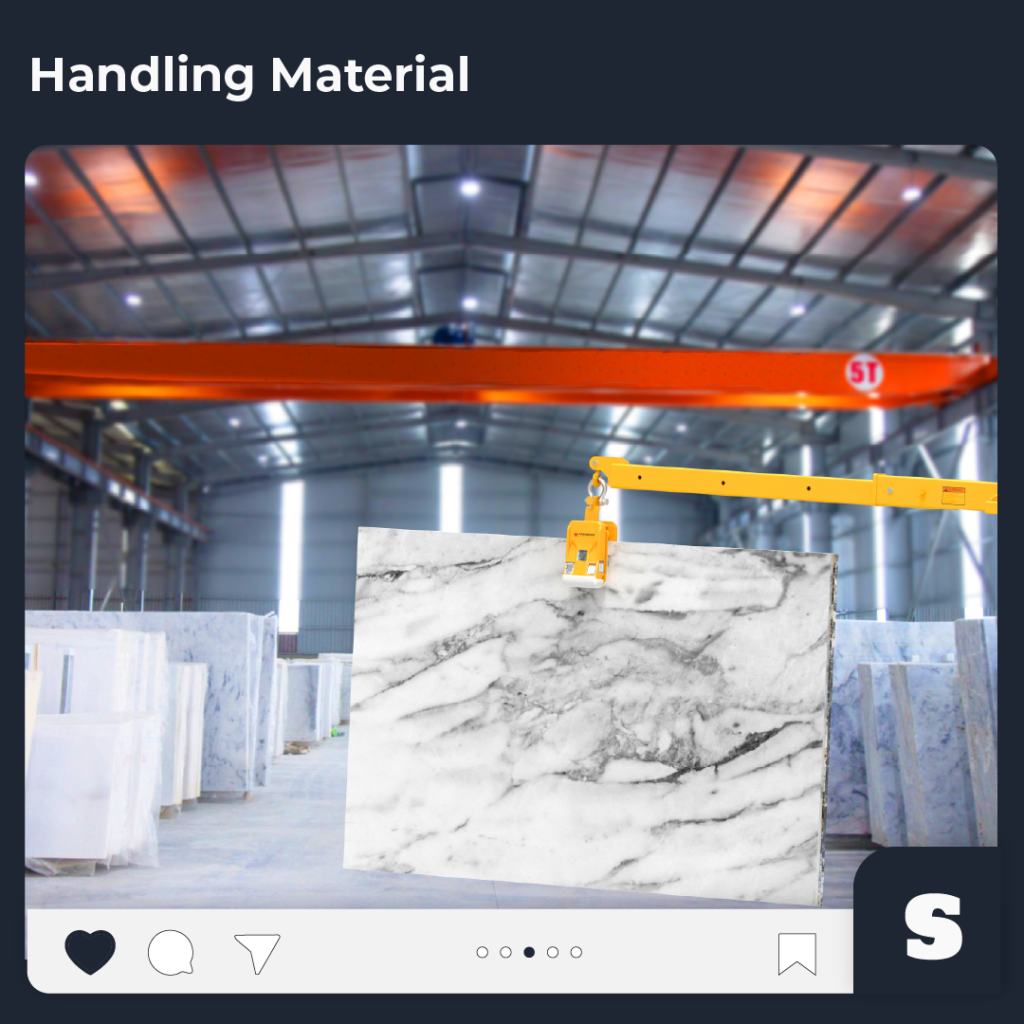

In today’s competitive stone industries, efficient material handling is not just a necessity—it’s a strategic advantage. Whether you’re dealing with raw stone blocks or finished products, leveraging the right handling material techniques and technologies can streamline operations, reduce waste, and enhance productivity. In this article, we explore the pivotal role of handling material in stone

In today’s competitive stone industries, efficient material handling is not just a necessity—it’s a strategic advantage. Whether you’re dealing with raw stone blocks or finished products, leveraging the right handling material techniques and technologies can streamline operations, reduce waste, and enhance productivity. In this article, we explore the pivotal role of handling material in stone processing, while also shedding light on material handling equipment, material equipment handling, and more.

The Importance of Handling Material in Stone Industries

Effective handling material practices ensure that stone materials are moved safely and efficiently from one stage to another. This is particularly critical in stone industries where heavy and often delicate products must be transported with care. By optimizing handling material techniques, businesses can reduce breakages, prevent costly downtime, and maintain the highest quality standards throughout production.

Advancements in Material Handling Equipment

The development of state-of-the-art material handling equipment has revolutionized the stone industry. Modern solutions, such as automated conveyors, forklifts, and specialized hoisting systems, allow for smoother transitions in the processing line. These tools are designed to handle various types of stone with precision and care, making them indispensable assets in any stone facility.

- Material Equipment Handling: In an era of rapid industrial evolution, integrating advanced material equipment handling systems can dramatically improve operational efficiency. These systems are engineered to offer flexibility and scalability, meeting the ever-changing demands of the stone sector.

- Material-Handling Equipment: It’s crucial to invest in high-quality material-handling equipment that not only meets current operational requirements but also anticipates future needs. Advanced safety features, energy efficiency, and robust design are key attributes that differentiate the best systems on the market.

Sourcing the Best Material Handling Equipment Manufacturers

Choosing the right material handling equipment manufacturers is vital for long-term success. Leading manufacturers offer a wide range of customizable solutions tailored to the specific requirements of stone industries. Their products are built with the latest technology and engineered for durability, ensuring that handling material challenges are met head-on.

- Material Handling Equipment Manufacturing: The process of material handling equipment manufacturing has evolved significantly, incorporating cutting-edge technologies such as automation and IoT. These innovations allow for better monitoring, predictive maintenance, and overall improved performance. For stone industries, this means smoother operations and a more responsive production line.

- Material Handling Equipment Suppliers: Reliable material handling equipment suppliers are the backbone of a successful handling material strategy. They not only provide high-quality equipment but also offer essential support services, such as installation, maintenance, and training. By partnering with reputable suppliers, stone companies can ensure that every aspect of their handling material process is optimized for maximum efficiency.

Integrating Handling Material Solutions into Stone Production

Integrating comprehensive handling material solutions involves careful planning and execution. Here are a few steps to consider:

- Assessment of Current Operations: Begin by evaluating your current handling material practices. Identify bottlenecks and areas where improved material equipment handling could reduce inefficiencies or hazards.

- Research and Investment: Look into the latest trends in material handling equipment. Compare different material handling equipment manufacturers and suppliers to find the most suitable options for your operations.

- Customized Solutions: Consider investing in bespoke material handling equipment that is specifically designed for stone industries. Tailored systems ensure that every aspect of handling material—from transportation to storage—is optimized.

- Training and Maintenance: Equip your workforce with the knowledge needed to operate new systems safely and efficiently. Ongoing training and regular maintenance can prevent breakdowns and prolong the life of your material handling equipment.

- Technology Integration: Utilize smart technologies to monitor equipment performance. By incorporating IoT sensors and data analytics, you can predict potential failures and address issues before they impact production.