Among the most crucial pieces of lifting equipment are lifting clamps. Whether you are working with a lifting clamp integrated into an advanced system

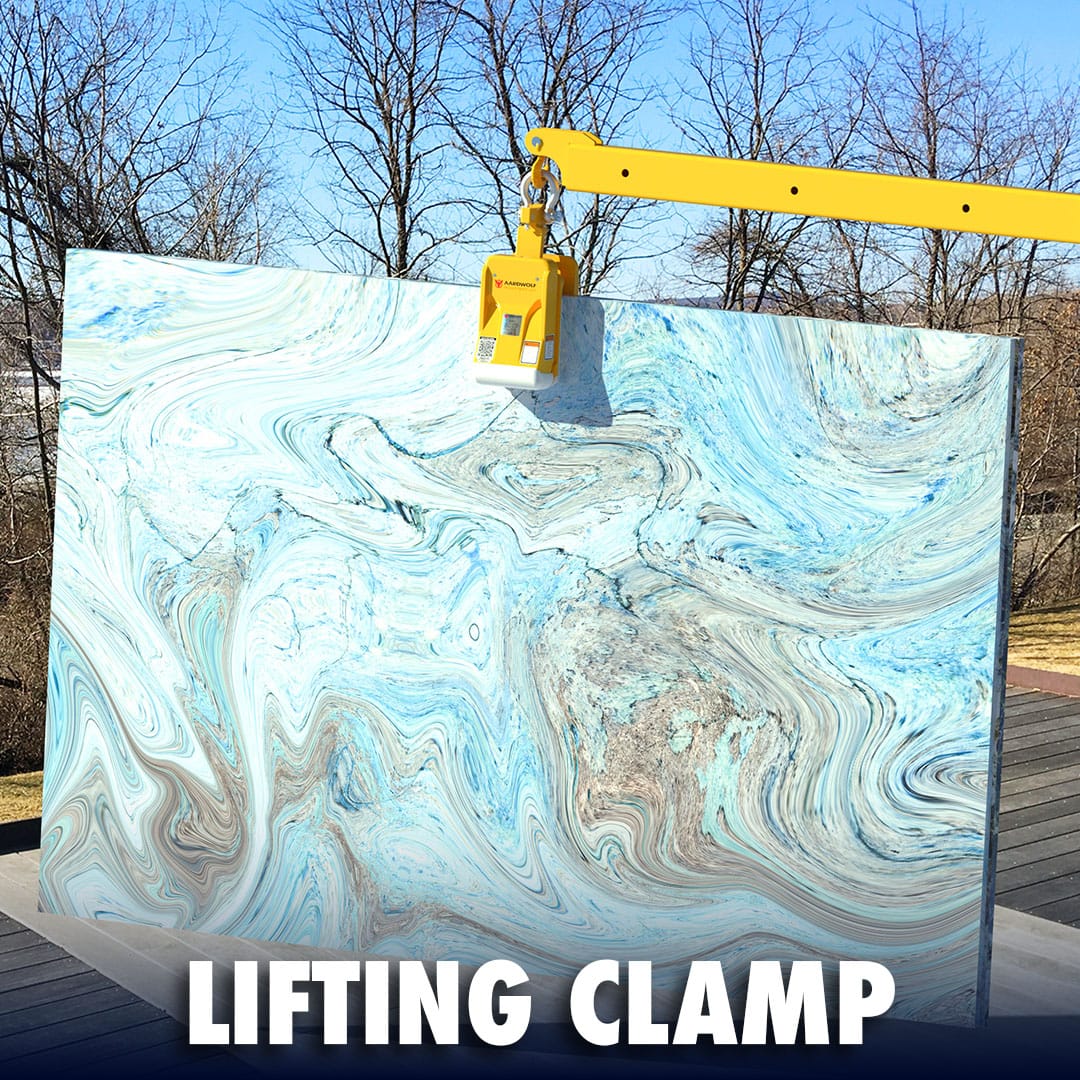

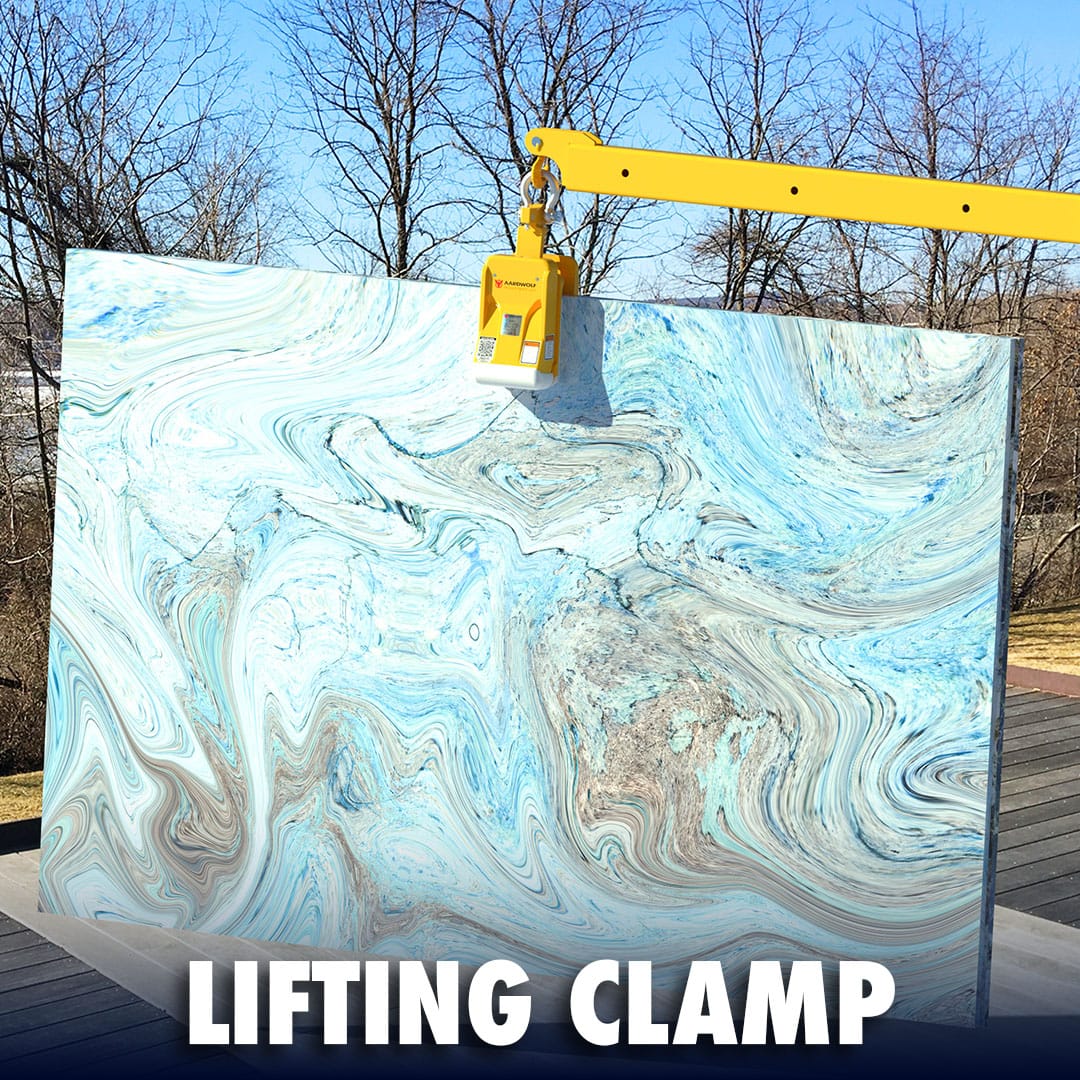

When it comes to safely and efficiently moving heavy materials such as stone, concrete, and metal plates, the right equipment is essential. Among the most crucial pieces of lifting equipment are lifting clamps. Whether you are working with a lifting clamp integrated into an advanced system like the aardwolf lifter, or selecting specialized lifting clamps for plates and slab lifters, making the right choice can significantly affect productivity and safety. This guide will explore everything you need to know about choosing the proper lifting clamps, including key features, types, applications, and maintenance tips.

Introduction to Lifting Clamps

Lifting clamps are mechanical devices designed to grip and secure heavy loads during lifting operations. They are widely used in industries such as construction, stone fabrication, manufacturing, and installation projects. Their purpose is to securely hold heavy items like slabs, plates, and even stone panels while they are being moved by a crane, forklift, or specialized machine.

In today’s dynamic industrial landscape, tools like lifting clamps have become indispensable due to their role in reducing manual handling risks and improving operational efficiency. They come in a variety of designs, including lifting clamp plates, lifting platt clamps, and plate lifting clamps, each tailored for specific applications.

Why Choosing the Right Lifting Clamp is Critical

Enhancing Workplace Safety

Handling heavy loads manually or with the wrong equipment can lead to accidents and injuries. The correct lifting clamp minimizes the risk of load slippage and ensures a balanced distribution of weight. This safety enhancement is vital not only for protecting workers but also for preventing damage to expensive materials.

Increasing Efficiency and Reducing Downtime

Properly selected lifting clamps streamline the lifting process by allowing for quick attachment and secure handling of heavy items. This efficiency translates to reduced project time and lower labor costs. Whether you’re using a high-end lifting clamp integrated with an aardwolf lifter or opting for a more traditional design, the right clamp can make all the difference.

Versatility in Material Handling

Lifting clamps are versatile. They are designed to work with various materials, from heavy slabs and stone panels to metal plates. With options like lifting clamps for plates and plate lifting clamps, you can choose the right tool for the job based on your project’s specific requirements. This versatility makes them suitable for both industrial and specialized tasks.

Key Factors to Consider When Choosing Lifting Clamps

Selecting the appropriate lifting clamp requires careful consideration of several important factors. Here are the main points to evaluate:

1. Load Capacity and Weight Distribution

Every lifting clamp has a specified load capacity. It is crucial to select a clamp that can comfortably handle the weight of the material you plan to lift. Overloading a clamp can lead to equipment failure and safety hazards. Look for clamps that ensure even weight distribution—this is especially important when lifting large plates or slabs where imbalance could cause damage.

2. Compatibility with Lifting Equipment

Ensure that the lifting clamps you choose are compatible with your existing lifting machinery. Whether you’re using a slab lifter, an aardwolf lifter, or other lifting devices, the clamp must integrate seamlessly with your equipment. Compatibility extends to the type of connection points, hydraulic systems, and even the software that may control automated systems.

3. Material and Build Quality

The durability of a lifting clamp is determined by the quality of materials used in its construction. High-quality steel and corrosion-resistant finishes are common in the best clamps available. When selecting a lifting clamp plate or lifting platt clamps, check for certifications and standards that indicate high build quality and longevity.

4. Ease of Operation

User-friendly design is a key factor, particularly when the clamps are used frequently. Look for features that make operation simple, such as intuitive locking mechanisms and quick-release functions. Ease of use reduces the learning curve for operators and speeds up the overall process.

5. Safety Features and Certifications

Modern lifting clamps often come equipped with safety features like emergency release mechanisms, load indicators, and redundant locking systems. Verify that the lifting clamps have been tested and certified by relevant safety bodies. This is essential in ensuring the equipment not only meets legal standards but also provides the highest level of safety on the worksite.

6. Versatility and Adaptability

Consider whether you need a versatile clamp that can handle a variety of materials. For instance, if your projects include both stone and metal components, a stone lifter configuration or a clamp designed for different plate sizes may be more suitable. Versatile clamps can be used across various applications, such as lifting slabs, lift slabs, or handling different types of plates.

Types of Lifting Clamps and Their Applications

Lifting Clamp Plates

Lifting clamp plates are designed specifically for lifting flat, heavy plates and slabs. These clamps distribute the load evenly, minimizing the risk of bending or damaging the material. They are ideal for applications in construction sites where large stone panels or concrete slabs need to be lifted and repositioned.

Plate Lifting Clamps

Plate lifting clamps are specialized for handling metal plates. They are often used in manufacturing and industrial settings where precision and secure holding are paramount. Their design ensures that the plates are securely gripped during the lifting process, reducing the chance of accidents or misalignment.

Lifting Clamps for Plates

These clamps are versatile and can be adjusted to accommodate plates of varying sizes and thicknesses. They are popular in workshops and fabrication environments where the materials might differ from one project to another. Their adaptability makes them a favored choice in industries that require frequent changes in the type and size of the load.

Integration with Advanced Lifting Systems

For those seeking the latest in lifting technology, many modern systems integrate lifting clamps with advanced machinery such as the aardwolf lifter. These systems often feature automated functions, which enhance precision and reduce the need for manual adjustments. When combined with a lifting clamp, these high-tech solutions bring together safety, efficiency, and versatility.

The Role of Stone Lifters

In the realm of stone fabrication and heavy material handling, stone lifters equipped with specialized lifting clamps have revolutionized the industry. They provide the necessary grip and support required to handle large stone panels safely and effectively. Whether you are lifting granite, marble, or engineered stone, the right stone lifter equipped with a robust lifting clamp ensures that your materials are moved without damage.

Applications of Lifting Clamps in Various Industries

Construction and Building Projects

In construction, lifting clamps are indispensable. They are used for tasks ranging from lifting heavy concrete slabs and stone panels to installing countertops and other fixtures. For instance, in Countertop Installation projects, precision and safety are paramount. Using the right lifting clamp during installation ensures that materials are placed accurately and securely, minimizing the risk of damage or misalignment. You can read more about the best practices in Countertop Installation.

Stone Fabrication and Installation

Stone fabricators rely heavily on lifting clamps to move and position large stone slabs and panels. A plate lifting clamp ensures that even the most delicate materials are handled with care. The ability to securely grip the stone not only enhances safety but also ensures that the finished product meets the highest standards of quality.

Industrial and Manufacturing Applications

In industrial settings, lifting clamps are used to move heavy metal plates and other large components. They are particularly valuable in manufacturing plants where efficiency and safety are critical. The versatility of lifting clamps for plates allows them to be used in different stages of production, from raw material handling to final assembly.

Infrastructure and Heavy Equipment

Large-scale infrastructure projects, such as bridge construction or the installation of industrial equipment, often require the use of specialized lifting clamps. These clamps can handle heavy loads while ensuring that the weight is evenly distributed. This minimizes stress on both the equipment and the material, which is crucial for long-term structural integrity.

How to Maintain and Inspect Lifting Clamps

Regular maintenance and inspection of lifting clamps are essential to ensure they continue to operate safely and efficiently. Here are some best practices:

Routine Inspections

Perform regular inspections to check for signs of wear, corrosion, or damage. Pay special attention to critical components such as the lifting clamp plate and locking mechanisms. Regular inspections can prevent accidents by identifying potential issues before they become severe.

Lubrication and Cleaning

Keep all moving parts well-lubricated to reduce friction and wear. Clean the clamps regularly to remove any debris or contaminants that could affect their operation. Proper cleaning not only extends the life of the equipment but also ensures that it functions optimally during each lift.

Professional Servicing

Schedule periodic servicing by professionals who are experienced in handling lifting equipment. A thorough professional inspection can identify any issues that may not be visible during routine checks. This proactive approach ensures that your lifting clamps remain reliable and safe for all applications.

Record Keeping

Maintain detailed records of all inspections, maintenance work, and any repairs performed on your lifting clamps. These records are invaluable for tracking the performance and longevity of the equipment, as well as for compliance with safety regulations.

Future Trends in Lifting Clamp Technology

As technology continues to advance, lifting clamps are also evolving. Here are some trends to watch for in the near future:

Automation and Smart Technology

The integration of smart technology into lifting clamps is on the rise. Automated features, remote controls, and even IoT connectivity are becoming more common. These advancements allow for real-time monitoring of load weights and operational parameters, further enhancing safety and efficiency.

Enhanced Material Engineering

New materials and engineering techniques are leading to the production of lighter yet stronger clamps. This trend not only improves the overall performance of lifting clamps but also enhances portability and ease of installation, especially in environments where weight and space are significant considerations.

Customizable Solutions

With the growing demand for versatility, many manufacturers are offering customizable lifting clamp solutions. These tailored options allow businesses to select clamps that precisely meet their unique operational requirements, from specific load capacities to unique connection systems.

Environmental Considerations

As industries become more environmentally conscious, there is a growing trend toward designing lifting clamps that are not only efficient but also eco-friendly. Innovations in hydraulic systems and energy-efficient designs are helping to reduce the environmental footprint of these essential pieces of equipment.

Conclusion

Choosing the right lifting clamp is a critical decision that can impact both safety and efficiency on your worksite. With a range of options available—from lifting clamp plates and lifting platt clamps to specialized plate lifting clamps and even systems integrated with an aardwolf lifter—it is essential to evaluate your specific needs carefully. Consider factors such as load capacity, compatibility, build quality, and ease of operation when making your selection.

By investing in high-quality lifting clamps, you not only enhance the safety of your operations but also improve efficiency, reduce downtime, and ultimately contribute to the success of your projects. Whether you are in the construction industry, stone fabrication, or manufacturing, the right lifting clamps will ensure that every lift is executed with precision and reliability.

For those interested in advanced lifting solutions, consider exploring a lifting clamp that integrates seamlessly with modern lifting systems. Additionally, if your project involves delicate tasks like Countertop Installation, refer to comprehensive guides on Countertop Installation to ensure every aspect of your project is handled with care.

In summary, a well-chosen lifting clamp is an investment that pays dividends in operational safety and efficiency. By understanding the various types available, the key features to look for, and the maintenance practices required, you can make an informed decision that supports your business’s long-term success. Whether you are handling stone, metal plates, or concrete slabs, the right lifting clamps will help you achieve precise, safe, and efficient lifts every time.

Embrace the advancements in lifting technology and make the smart choice for your next project. With the proper equipment at your disposal, you’ll not only safeguard your workforce but also enhance your project’s overall productivity and success.